Overview

Since 2002, Phoseon Technology has pioneered the use of LEDs for UV curing applications with a 100% focus on UV LED curing technology. Phoseon patented Semiconductor Light Matrix (SLM)™ technology encapsulates LEDs, Arrays, Optics and Cooling to maximize UV LED curing performance. Each of these four components are strictly engineered into a system that provides maximum UV energy and superior performance while also increasing long-term robustness for demanding applications.

UV LED Basics: A Brief Introduction into UV LED Systems

Light Emitting Diodes (LEDs)

Light Emitting Diodes (LEDs) are solid state devices that produce light when an electrical current flows from the positive (anode) side of the circuit to the negative (cathode) side. Phoseon builds complete light engines from individual diodes versus using pre-packaged LEDs. This allows Phoseon to match individual LED characteristics with other components to maximize the total UV energy.

As the base building block, this is the first choice a UV LED lamp supplier has to make. It is a critical choice that impacts the remainder of the systems architecture and design. Simply put, an LED is a solid-state device that produces light when an electrical current is allowed to flow from the positive (anode) side of the circuit to the negative (cathode) side.

Not all LEDs are built the same nor do they exhibit the same characteristics. UV LED lamp suppliers have critical choices to make as to the quality, type, material and shape of LED for their systems. Key LED characteristics considered by each UV LED lamp supplier include wavelength and UV output.

Wavelength: The wavelength emitted from an LED is controlled using differing amounts of dopants such as aluminum, gallium or indium derivatives during the manufacturing of the LED. The general rule of thumb is that the shorter the wavelength, the lower the peak UV output available from the die.

The UV LED supplier must weigh the trade‐offs between wavelength and the associated total energy with cure rate. Chemistry plays a significant role in this discussion. Some applications, due to their specific chemistry, require a given wavelength. However, for many applications a small shift in the peak wavelength will have no impact as the absorption of the UV by the photoinitiator which kicks‐off the reaction has a broad absorption range.

The output of a single UV LED is measured in milliwatts (mW) at a nominal input voltage and current. UV LED output has shown considerable improvement in recent years where specifications for LEDs from various vendors have improved significantly. This improvement shows the LED vendors have and will continue to improve the output of UV LEDs, which only provides a better foundation for the UV LED curing lamps that utilize them.

Arrays

Arrays are a grouping or clustering of individual LEDs. The number, type, and size of LEDs; the shape of the array; and the method of electrically connecting the LEDs all impact the array. Phoseon’s array architecture is targeted for both the product, whether air or water cooled, and the target application to insure the optimal performance and reliability for the system manufacturer.

Arrays are the second area where suppliers can begin to differentiate their product offerings. How the LEDs are combined, the number and type of LEDs chosen, the shape of the array, the method of electrically connecting the LEDs, and even the size of the LEDs all have significant impact on the performance of the system. If built correctly, it can be a high power UV LED array.

Most applications require UV LED curing systems that consist of more than one LED or LED array in order to achieve not only the desired throughput but to meet the demands for curing applications where the media can be 1‐2m wide. Therefore, a key question is if the LED array can be uniformly scaled. UV LED curing lamps can have a continuous scalable array that provides for better uniformity or a discrete array package that can be scaled, but doesn’t provide the same uniformity of output.

Some LED manufacturers only sell their LEDs pre‐packaged into arrays or assemblies that they feel maximize the UV output. UV LED lamp system suppliers that purchase pre‐packaged arrays have typically made a tradeoff between faster time‐to‐market and less differentiated lamps versus a slightly longer time‐to‐market and maximizing UV power. This is an area where UV LED lamp suppliers can differentiate themselves based on the suppliers’ architecture and engineering capability where two suppliers can take the same batch of LEDs and achieve very different performance in the end product.

Optics

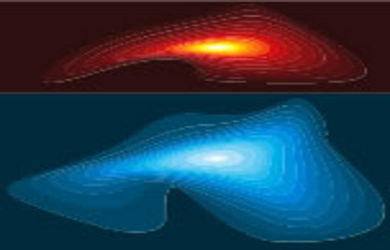

After choosing individual diodes and implementing application-specific arrays, Phoseon then layers optical technologies to direct energy towards the substrate or material to be cured. This use of optics has three benefits: 1) it maximizes the amount of UV energy applied to the material and 2) it lowers the heat generated by the array, and 3) it provides for application specific focused energy.

The UV LED optics is one of the most important differentiators in lamps. The science of optically improving the LEDs to maximize their UV output is key to the lamp’s final capability. Based on the end application the optical engineer has to decide what shape, form, and material best utilizes the LED’s unique characteristics. Next they have to balance the fact the LEDs are a ‘flood’ type of light, unlike a focused mercury lamp where the light is captured by a reflector and directed to a specific point, focal length.

The optical engineer is challenged to use methods to ensure the maximum amount of light ‘escapes’ at the desired irradiance through the window/glass towards the material. LED Lamp suppliers have used various, confidential methods to maximize the UV LED light.

While an end‐user or OEM should not necessarily be concerned with how the optics are provided in the UV LED lamp, they should understand if the supplier has the ability to improve their design for their specific application needs.

Cooling

UV LEDs will last past 20,000 hours if they maintain proper operating temperatures. As LEDs emit more energy, they also generate more heat, which needs to be managed. Phoseon uses patented thermal management techniques that remove excess heat from the system while providing a consistent operating temperature for the diodes to function at maximum performance over their operating lifetime.

LED cooling is very important for UV light sources. As any reader knows after using a notebook PC on their lap for a length of time, the by‐product of solid‐state devices is heat. UV LEDs transfer about 15‐25% of the received electrical energy into light. The remaining 75‐85% is transferred as heat; thus, the need to cool the LED arrays.

Currently, UV LED arrays are cooled with either air or liquid. It is important to note that as the LEDs emit higher output power, the more heat is generated. Thus in the race to build ever higher irradiance products, the ability of suppliers to control and remove heat has become more crucial to building reliable systems. As the quality of LEDs improves and the irradiance increases, so does the need to remove the heat. OEMs and end‐users do not want to spend more on the LED cooling of the light sources.